AI Server Power Revolution: 800V HVDC Architecture and the Future of Magnetic Components

AI Server Power Performance Soars

The past decade has seen a steady climb in server power efficiency, but AI is rewriting the rules at an unprecedented pace. Power density has surged by 500%, dynamic response now surpasses 5 A/μs, and efficiency thresholds are being pushed beyond 96%. This acceleration stems from two converging forces: the rise of third-generation semiconductors and the relentless march toward magnetic component densities reaching 1000 W/in³.

NVIDIA’s May 2025 announcement of its next-generation 800V high-voltage direct current (HVDC) data center power architecture marked a turning point. Designed for hyperscale AI compute centers, this architecture doesn’t just optimize power—it redefines it. By directly converting 13.8 kV AC from the grid into 800V DC at the rack, inefficiencies inherent to traditional multi-stage, low-voltage systems are eradicated. Copper losses, spatial inefficiencies, and conversion overhead are dramatically reduced, setting a new benchmark for “three highs”: high power, high density, and high dynamic performance.

This shift is not incremental—it has the potential to reconfigure the very ecosystem of the power supply industry.

Third-Generation Semiconductors: The Engine of Efficiency

The choice of power devices differs dramatically between conventional and high-voltage architectures. While traditional single-phase AC designs rely on 650V-rated devices, the HVDC approach demands both 650V and 1200V capability. Here, silicon carbide (SiC) MOSFETs emerge as the clear frontrunner.

SiC’s ability to minimize switching and conduction losses under high voltage and high current makes it indispensable for this new paradigm. Its compact footprint also complements the space constraints of high-density rack designs. Gallium nitride (GaN) HEMTs and superjunction MOSFETs have roles to play, but their current voltage limitations prevent them from shouldering the 1200V burden.

In essence, SiC enables what NVIDIA envisions: reducing copper consumption, minimizing energy dissipation, and simplifying data center-level power conversion. This isn’t just an efficiency upgrade—it’s an infrastructural necessity for racks drawing more than 1 MW.

Magnetic Components: Shifting Roles in AI Power Topologies

The transformation in power architecture directly reshapes the role of magnetic components. Current AI server power modules typically adopt one of two circuit topologies:

For 5–8 kW systems: Bridgeless PFC paired with LLC resonant converters.

For 15 kW systems: Vienna rectifiers combined with LLC resonant converters, often employing multi-phase parallelization for scalability.

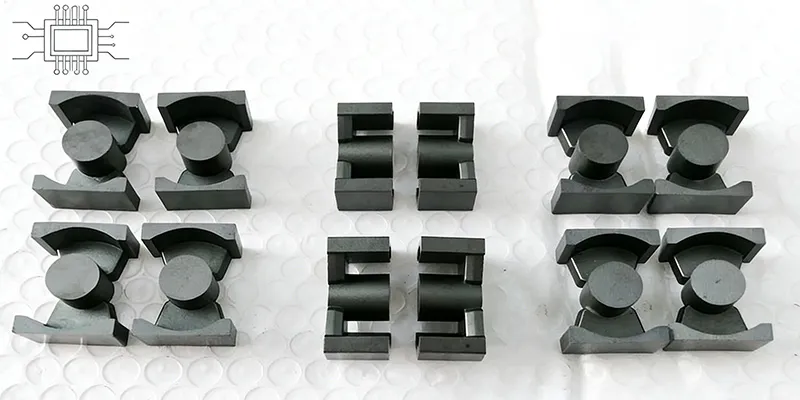

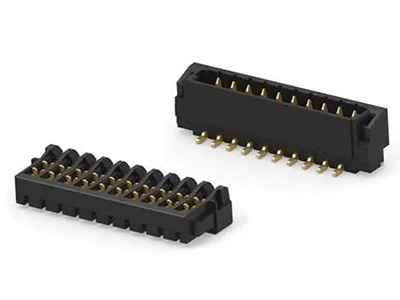

Magnetic component count and configuration are dictated by these topologies. For example, a bridgeless PFC setup typically involves:

Two PFC inductors with toroidal designs utilizing high-flux cores.

Two LLC transformers, often PQ or ETD type, or integrated magnetic designs.

Two to four LLC resonant inductors.

By contrast, Vienna rectifier-based designs demand more components. A 15 kW solution from Bolande Electronics, using three-way parallelization, integrates three PFC inductors, three LLC transformers, and three LLC inductors. Optimizations have already halved the original counts through magnetic integration, reducing the total major components to nine.

The message is clear: magnetic integration isn’t just a technical advantage—it’s a survival strategy.

Breaking Density Barriers: PCB-Winding Transformers

The gravest challenge for magnetic components in AI power systems lies in the dual demand for ultra-low loss and extreme compactness. Frequencies exceeding 200–300 kHz amplify core hysteresis and eddy losses, while skin and proximity effects multiply winding losses. Advanced techniques—such as Litz wire, flat conductors, and optimized geometries—are no longer optional but mandatory.

Bolande’s 15 kW system illustrates this evolution: where conventional designs allocated 20–30% of total losses to magnetic elements, optimized designs now constrain them to around 13%. Every watt conserved amplifies the viability of high-frequency, high-density operation.

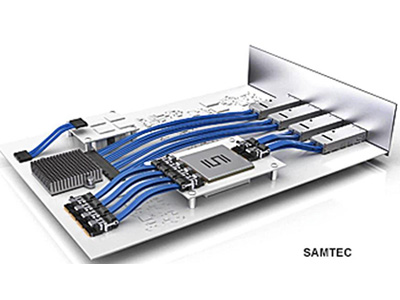

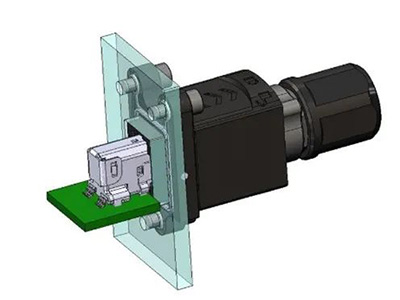

Yet form factors themselves are changing. PCB-winding transformers, once a niche approach, are emerging as the linchpin for next-generation DC-DC modules. These transformers, with their precision, reproducibility, and integration potential, can deliver densities between 300 W/in³ and 1000 W/in³. Coupled with GaN-based switching, they are poised to become the de facto standard for AI-grade server power.

PCB-Winding Transformers: From Trend to Standard

At APEC 2025, nearly all HVDC server power solutions—whether 400V or 800V—employed PCB-winding transformers. Industry leaders are aligning rapidly. Yang Xibin, CEO of Changsha Techosed, projects that within 3–5 years, PCB windings will replace more than 50% of traditional transformers in high-power scenarios, with near-total adoption in AI server applications.

The reasons are compelling: higher structural freedom, superior manufacturing precision, and unrivaled scalability in compact systems. As liquid cooling spreads across data centers, freeing space and reshaping thermal management priorities, PCB transformers will occupy an even stronger position in the hierarchy of power components.

Mapping the 800V Supply Chain

NVIDIA’s 800V initiative, alongside competing 400V HVDC approaches, draws inspiration from the electric vehicle industry. Both voltage tiers can leverage the mature ecosystem of 800V EV components—ranging from semiconductors to magnetic elements—accelerating time-to-market and lowering costs.

Suppliers already active in automotive 800V platforms are strategically positioned. Their accumulated expertise, proven materials, and robust processes allow them to pivot seamlessly into the AI data center space. This cross-industry synergy explains why NVIDIA confidently targets 2027 for mass deployment.

Conclusion

AI’s relentless appetite for computation is igniting a new epoch in power conversion. Power density leaps, SiC-driven efficiency gains, and magnetic component reinvention converge to form an unprecedented technological upheaval.

NVIDIA’s 800V HVDC architecture signals more than a roadmap—it anchors the industry’s trajectory toward high efficiency, integration, and frequency. PCB-winding transformers, once a novel experiment, now stand on the cusp of becoming the indispensable backbone of AI server power delivery.

The race is unmistakable: only those who master the nexus of semiconductors, topology, and magnetic innovation will command the next generation of AI infrastructure. In this contest, adaptability is not optional—it is the price of survival.

Shenzhen Gaorunxin Technology Co., Ltd