Product Spotlight | TE Connectivity, Hirose Electric, and Stäubli Unveil Cutting-Edge Connector Innovations

As global industries pivot toward electrification, automation, and renewable energy, the demand for high-performance, application-specific connectors has surged. In response, leading manufacturers TE Connectivity, Hirose Electric, and Stäubli have each introduced a new generation of connector technologies that break conventional limitations. These innovative offerings not only enhance connectivity performance but also address deep-rooted industry pain points in electric vehicles, industrial automation, and photovoltaic systems.

From high-voltage contactors engineered for megawatt-level EV fast charging to compact, waterproof industrial connectors and localized photovoltaic solutions, these differentiated technologies reflect a strategic commitment to both performance excellence and regional relevance.

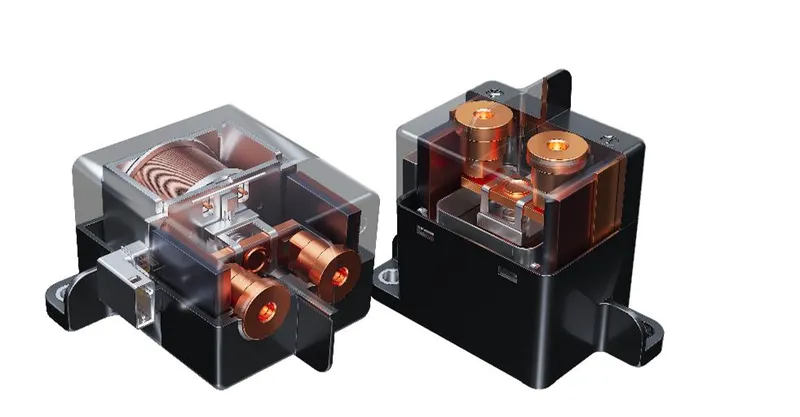

TE Connectivity: High-Performance Anti-Stick High-Voltage Contactors

The arrival of the megawatt fast-charging era has underscored the urgency for compact and reliable contactor solutions capable of withstanding extreme voltage and current conditions. TE Connectivity’s latest EVC Series answers this demand with a powerful new generation of high-voltage contactors that embody advanced anti-stick architecture and ruggedized design.

Key Innovations:

Anti-Stick Design Architecture

The EVC contactors incorporate proprietary composite materials and a novel contact structure that virtually eliminates the risk of welding under short-circuit or high-current events. Rated for over 8000A, these units deliver a 20–30% increase in current-handling capacity compared to standard alternatives, meeting the rigorous GB38031-2025 Chinese national standard.Enhanced Shock Resilience

Raising the bar from the industry norm of 20G to an impressive 50G, the contactors demonstrate omnidirectional shock resistance across the X, Y, and Z axes—making them ideal for harsh vehicular and industrial applications.Miniaturization with Energy Efficiency

Within the 200A–400A operating range, the compact EVC400 variant boasts a 39% volume reduction over equivalent models. Coupled with a smart PWM coil control system, the contactors offer finely tuned contact force while reducing energy consumption.

These enhancements position TE’s EVC Series as an indispensable component for next-gen electric vehicles and high-power energy systems, especially where reliability, space, and safety intersect.

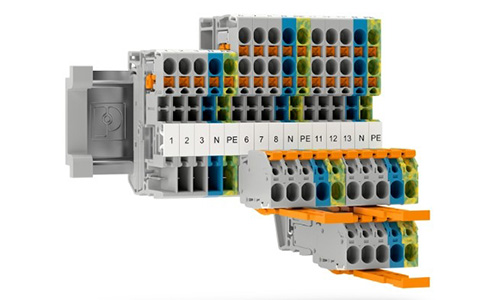

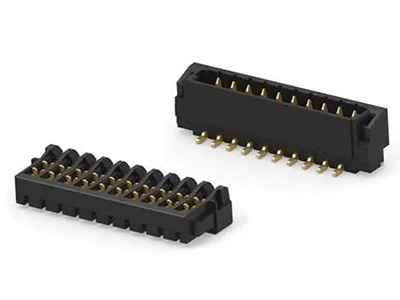

Hirose Electric: ixIndustrial™ Waterproof Connectors for Compact Industrial Networking

As industrial automation evolves, communication reliability and environmental resilience are no longer negotiable. Traditional RJ45 connectors often fall short under demanding space and ingress protection requirements. Addressing these challenges head-on, Hirose Electric introduces the ixIndustrial™ Waterproof Connector, combining high-density design with IP67-rated sealing.

Standout Features:

Superior IP Protection

Fully mated assemblies comply with IP65/IP67 standards and include integrated dust caps for additional safeguarding. The result is a robust communication interface, impervious to industrial contaminants and moisture.Total Compatibility with Existing IX Series Sockets

The waterproof plug integrates seamlessly with all existing IX-series receptacles, streamlining development timelines and simplifying inventory management.Space-Saving Form Factor

With a 45% reduction in volume compared to legacy RJ45 connectors, the ixIndustrial™ ensures optimal use of panel space, supporting the densification of modern industrial systems.Push-Pull Locking Mechanism with Anti-Misplug Features

The dual-locking push-pull design mitigates vibration-induced disconnections and human error during installation—critical for high-reliability industrial environments.Multi-Cable Flexibility

Supporting AWG22–28 wire gauges, the connector adapts easily to diverse cable types and layout requirements, enhancing design versatility.

Application Scenarios:

Engineered for factory automation and smart machinery, these connectors excel in applications such as servo drives, PLCs, machine vision systems, industrial robots, and safety controllers. The ixIndustrial™ serves as a compact yet formidable interface in environments where uptime and compactness are vital.

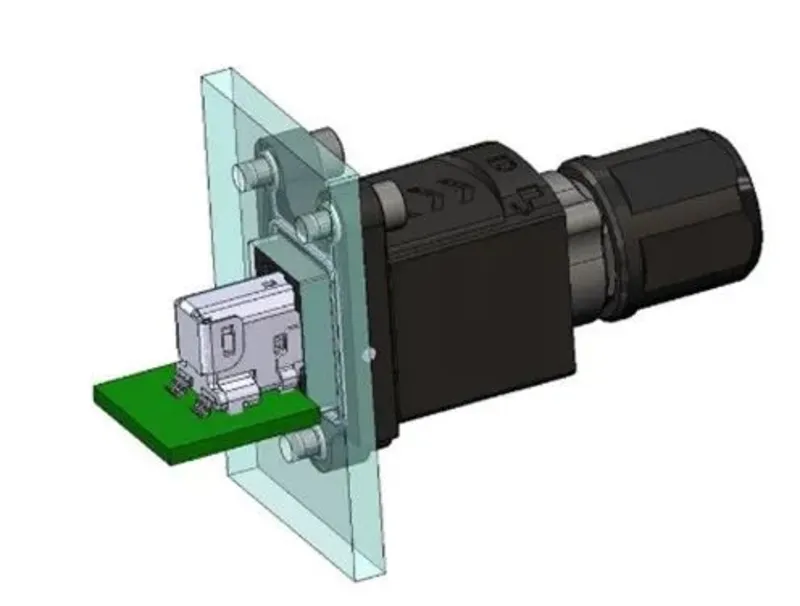

Stäubli: First China-Made MC4-EVO1 Photovoltaic Connector

In the realm of photovoltaic energy, reliable connectivity is paramount. As a pioneer and global leader in solar connector technology, Stäubli deepens its commitment to the Chinese market with the release of its first locally manufactured connector: the MC4-EVO1. This launch signifies more than product availability—it embodies Stäubli’s localization strategy and dedication to regional integration.

Defining Characteristics:

Localized Innovation

Co-developed by Stäubli’s Swiss and Chinese engineering teams, the MC4-EVO1 is fully produced in China. This approach enhances responsiveness to local market needs and reduces lead times.Rigorous Certification

The MC4-EVO1 has secured TÜV BauartMark certification, following extensive third-party validation against IEC EN 62852 standards. This ensures compliance with global safety and performance benchmarks.

Target Applications:

Purpose-built for photovoltaic systems, the MC4-EVO1 guarantees efficient and secure interconnections in solar installations. It supports the ongoing transformation of the energy sector by reinforcing the reliability of renewable infrastructure.

Conclusion: Differentiated Innovation Empowering Industry Transformation

From TE Connectivity’s anti-stick contactors engineered for high-power EV applications, to Hirose Electric’s miniaturized waterproof connectors designed for tight industrial spaces, and Stäubli’s localized photovoltaic connectors tailored for China’s booming solar sector—each innovation reflects a strategic blend of performance, resilience, and adaptability.

Collectively, these advancements are catalysts for technological evolution in electric vehicles, smart manufacturing, and green energy. By overcoming entrenched limitations with forward-thinking engineering, these products lay the foundation for smarter, cleaner, and more efficient systems—propelling global industries toward a sustainable future.

Shenzhen Gaorunxin Technology Co., Ltd