Understanding Semi-Rigid Coaxial Cables: Structure, Performance, and Applications

What Is a Semi-Rigid Coaxial Cable?

A semi-rigid coaxial cable is a specialized transmission medium designed for precision, minimal signal degradation, and high-frequency stability. It offers a balance between mechanical rigidity and configurability, making it ideal for systems where signal fidelity is non-negotiable. These cables are extensively employed in telecommunications, RF circuits, aerospace and defense platforms, and high-accuracy test instrumentation.

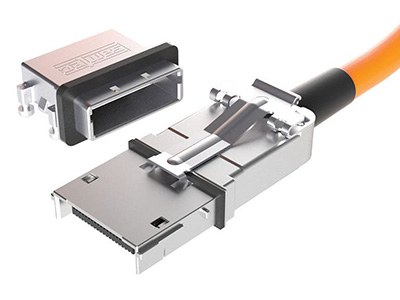

The cable's structure is inherently simple yet exceptionally effective: a solid metal core conductor—commonly copper—is encapsulated within a dielectric insulator and further shielded by a continuous metal outer sheath. Unlike flexible coax cables with braided shielding, the semi-rigid variant features a solid, bendable metallic tube—often copper or aluminum—that significantly reduces electromagnetic interference (EMI) while maintaining superior shielding effectiveness.

Customized Assembly and Stability in Performance

Manufacturers such as SV Microwave specialize in crafting semi-rigid coax assemblies tailored to precise dimensional and geometric requirements. These assemblies maintain consistent power delivery even under demanding environmental conditions.

Unlike braided-flexible counterparts, the continuous metallic shield ensures electromagnetic integrity and structural stability. Variations in temperature can alter the electrical and mechanical properties of both the dielectric and metallic materials. Therefore, using stable, pre-formed cables in critical systems mitigates signal fluctuation and component failure. These cables are offered in a diverse range of diameters and are compatible with numerous connector types to suit specific engineering designs.

Design Specifications

Standardization is a hallmark of semi-rigid coaxial cable manufacturing. These cables conform to rigorous military-grade specifications, ensuring reliability and repeatable performance.

Winchester Interconnect, for example, produces semi-rigid coaxial cables that adhere to MIL-DTL-17 (formerly MIL-C-17) standards. This compliance guarantees performance benchmarks in terms of attenuation, impedance uniformity, and environmental resilience.

Manufacturing Considerations

Fabricating semi-rigid coaxial cables requires meticulous precision and the use of specialized tools. During installation, bending or shaping the cable must be conducted carefully to preserve the structural integrity of the outer conductor. Deformation or fractures in the shielding layer can compromise the cable's electromagnetic performance and lead to unpredictable signal behavior.

Although soft metals like aluminum or annealed copper allow some degree of manual manipulation, the use of precision tools is strongly recommended to avoid internal damage. Proper handling ensures the cable retains its designed impedance and minimizes signal reflection or attenuation.

Key Characteristics

Semi-rigid coaxial cables offer a host of performance-enhancing features that make them indispensable in high-frequency signal chains:

Frequency Capability: Most semi-rigid cable assemblies support frequencies up to 65 GHz. With the integration of ultra-miniature connectors like the 1.0mm series, performance can extend to 110 GHz for cutting-edge RF applications.

Dimensional Range: Available in diameters ranging from 0.020 inches to 0.250 inches, enabling tight spatial integration and minimal layout interference.

Impedance Standards: Typically engineered for 50 ohms—standard for RF and microwave applications—or 75 ohms for video and broadcast systems.

Insertion Loss: For a 50-ohm configuration, loss ranges from 0.1 to 0.5 dB/m within the 1–10 GHz band, depending on the specific cable geometry and materials. At higher frequencies, losses generally increase due to skin effect and dielectric loss.

Operating Bandwidth: From DC up to 40 GHz, suitable for broad-spectrum applications including analog, digital, and mixed-signal transmission.

Dielectric Withstand Voltage (DWV): Rated typically between 500V to 2000V, influenced by the dielectric medium (e.g., PTFE or expanded PTFE).

Shielding Effectiveness: Exceptional RF leakage protection exceeding 90 dB, with configurations incorporating solid tubing, foil, or hybrid braid-foil composites.

Thermal Range: Operational from -55°C to +200°C, ideal for use in extreme industrial, aviation, and defense environments.

Notable Manufacturers and Industry Applications

Semi-rigid coaxial cables serve as critical infrastructure in a wide array of high-reliability sectors:

Data Communications & Telecom: For low-loss, interference-free signal routing in base stations, routers, and backhaul systems.

Test & Measurement: High-frequency test fixtures, network analyzers, and microwave calibration kits.

Medical Equipment: Imaging systems, diagnostic devices, and minimally invasive surgical tools requiring precision RF signal transmission.

Military & Aerospace: Radar systems, missile guidance modules, satellite payloads, and avionics subsystems.

Industry-leading suppliers include Molex, Radiall, Rosenberger, Samtec Inc., SV Microwave, and Times Microwave, all offering high-precision semi-rigid solutions compliant with international standards and mission-critical specifications.

Conclusion

Semi-rigid coaxial cables are not merely transmission lines—they are engineered enablers of high-frequency precision. Whether deployed in the cockpit of a supersonic jet, embedded within a telecom repeater, or integrated into medical diagnostic arrays, their mechanical integrity and electrical performance define operational success. The convergence of structural rigidity and electromagnetic excellence makes them the backbone of modern RF and microwave systems.

Shenzhen Gaorunxin Technology Co., Ltd