Understanding Waterproof and Dustproof Ratings in Connectors

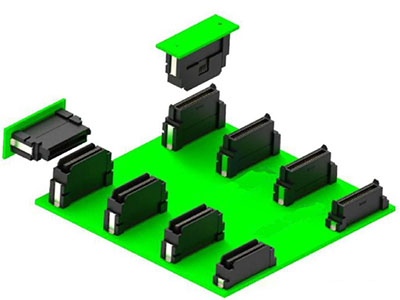

In the realm of connector selection, customer requirements vary widely. A frequent request centers around waterproof and dustproof capabilities—critical performance factors across myriad applications. Whether a connector is destined for the harshness of marine environments, the exposure of industrial machinery, or the unpredictability of automotive settings, the right protection grade ensures operational longevity and safety. This article provides a concise yet thorough overview of the ingress protection (IP) standards that govern these classifications, offering clarity amidst a sea of specifications.

International Standards for Waterproof and Dustproof Ratings

The waterproof and dustproof standards for connectors are primarily based on two internationally recognized frameworks: the IEC 60529 standard issued by the International Electrotechnical Commission, and the ISO 20653 standard. In China, the QC/T 413 standard acts as the domestic guideline for vehicular connector protection.

Each standard caters to different industries and applications. While IEC 60529 is widely applicable in general electronic and electrical domains, ISO 20653 is geared more toward vehicular and outdoor environments. These standards are not static—they evolve to meet the demands of emerging technologies and usage scenarios.

IP Rating: The Dual-Number Code Explained

The Ingress Protection (IP) code is composed of two digits, each representing a specific aspect of environmental protection:

First Digit – Protection Against Solid Intrusion (Dust): Ranges from 0 to 6. A higher number signifies better protection against particulate matter.

Second Digit – Protection Against Water Penetration: Ranges from 0 to 8 (with the addition of 9K in specific standards), denoting resistance to moisture and liquid ingress.

Dustproof Levels: First Digit of IP Code

| Rating | Protection Level |

|---|---|

| IP0X | No protection against solid objects. |

| IP1X | Protects against objects >50 mm, e.g., accidental hand touch. |

| IP2X | Blocks objects >12.5 mm, like fingers. |

| IP3X | Shields from items >2.5 mm, such as tools or thick wires. |

| IP4X | Prevents ingress of solids >1 mm in size. |

| IP5X | Not entirely dust-tight, but internal operation is unaffected. |

| IP6X | Fully dust-tight; complete protection against airborne particulates. |

Waterproof Levels: Second Digit of IP Code

| Rating | Protection Criteria |

|---|---|

| IPX1 | Vertical water drips cause no harm. Ideal for light rain under cover. |

| IPX2 | Water dripping at 15° tilt poses no threat. Suitable for slightly angled installations. |

| IPX3 | Withstands water spray from up to 60° from vertical. |

| IPX4 | Protects against splashes from all directions. |

| IPX5 | Endures low-pressure water jets from any angle. |

| IPX6 | Withstands strong water jets; suitable for industrial hose cleaning. |

| IPX7 | Handles submersion up to 1 meter for 30 minutes. Useful for temporary immersion. |

| IPX8 | Endures continuous immersion beyond 1 meter, as defined by manufacturer specifications. |

| IPX9K | Survives high-pressure, high-temperature spray. Originally for automotive, now cross-industry. |

IPX9K: The Apex of Waterproof Protection

Initially developed for automotive connectors under ISO 16750, DIN 40050, and ISO 20653, IPX9K represents the most extreme level of water resistance. This rating is now included in domestic Chinese automotive standards such as QC/T417.1-2001, addressing the needs of high-demand environments.

IPX9K-rated connectors can withstand high-pressure, high-temperature water jets, making them ideal for:

Food and beverage processing lines

Agricultural machinery exposed to mud and chemical sprays

High-pressure washdown areas in public transport or heavy-duty vehicles

The use of IPX9K has since expanded far beyond vehicles, responding to industry needs for superior sanitation, hygiene, and resistance to fluid intrusion under harsh conditions.

Typical IP Ratings in Connectors and Application Scenarios

| Rating | Description | Application Examples |

|---|---|---|

| IP67 | Dust-tight and protected against temporary immersion in water (up to 1 meter for 30 minutes). | Outdoor LED lighting, automotive sensors, kitchen appliances. |

| IP68 | Dust-tight and capable of long-term immersion under pressure-defined conditions (e.g., 2 meters for 2 hours). | Submersible pumps, underwater cameras, oceanographic instruments. |

| IP69K | Highest grade; withstands high-pressure, high-temperature washdowns. | Food processing lines, off-road vehicles, robotic cleaning systems, high-end car exteriors. |

Evolving Demands in Waterproofing: A Future Outlook

With the advent of intelligent transportation, underwater robotics, and high-end electric vehicles, waterproof standards are being redefined. Not only are connectors expected to resist environmental aggression, but they must also maintain signal integrity and mechanical stability over long operational cycles.

Manufacturers are investing in advanced sealing materials, precision-molded housings, and multi-layered protective coatings. The move towards miniaturization without compromising protection is accelerating innovation, making connector design a frontier of material science and mechanical engineering.

Conclusion

Understanding the nuances of IP ratings is vital in selecting the right connector for a given application. Whether facing desert dust or monsoon deluges, the correct specification can mean the difference between optimal performance and premature failure. As standards evolve and applications diversify, so too must our approach to environmental protection in connector systems.

Shenzhen Gaorunxin Technology Co., Ltd